Watchcases comprised of an innovative ceramic

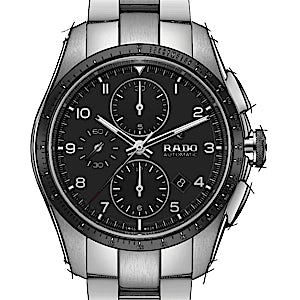

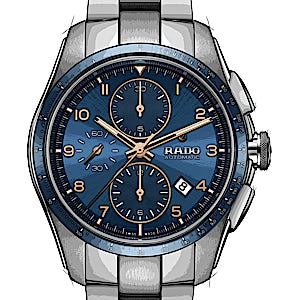

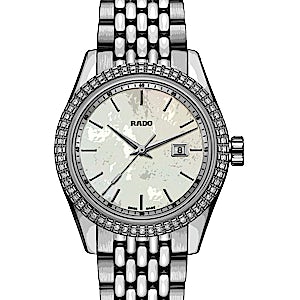

The case of the Rado Hyperchrome convinces not only as a stylish piece of jewellery but is also celebrated as a novelty when it comes to the construction of ceramic watches. An elaborate high-pressure injection process allows for the case of the watch to be produced in one single piece and, therefore, does away with the need for a steel cage that is typical of ceramic timepieces. As a result, the timepiece is extremely light, scratch resistant, and comfortable around the wrist. The later stages of the high-tech ceramic process consist of placing the case of the watch into a special oven, where a plasma column activates gases at 20,000°C. The gases then permeate the surface of the ceramic case, which modifies its surface structure, resulting in an exquisite permanent lustre.

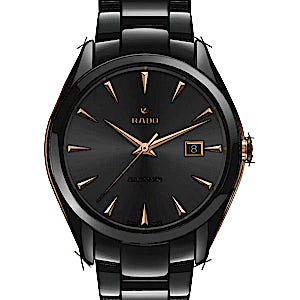

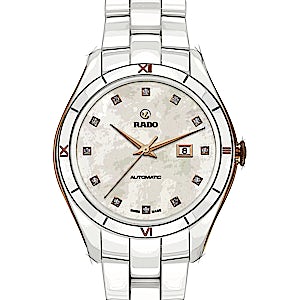

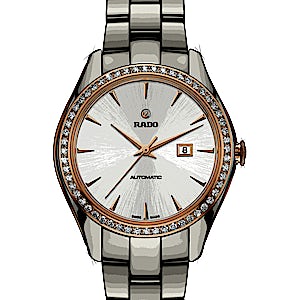

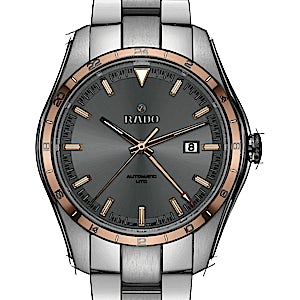

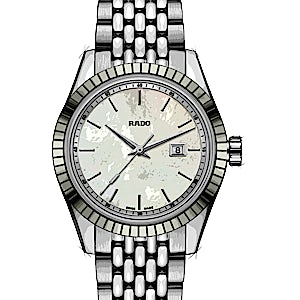

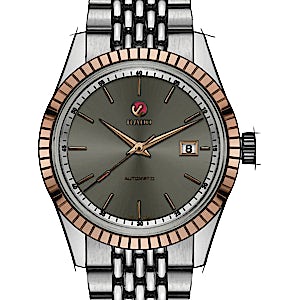

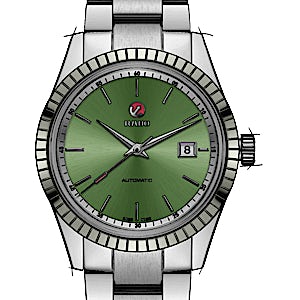

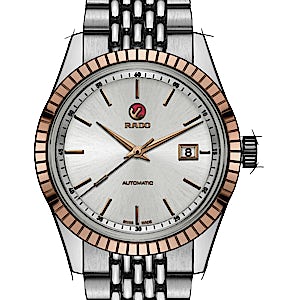

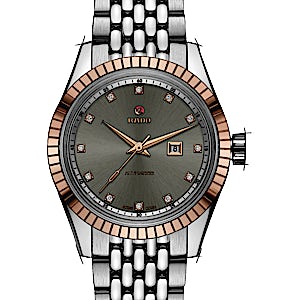

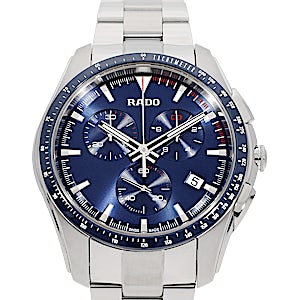

The so-called monobloc case is cleverly integrated with watch lugs that present a unique aesthetic and a distinctive form. Depending on the preference of the client, the watch models are available in a sleek black or a pure white high-tech ceramic. All the timepieces from the line impress with a hardness of 1250 Vickers. Colour matching elements on the dial of the watch perfect the overall aesthetic of the timepiece and ensure that the optically contrasting indices, counters, and chronograph pushers are highly visible.